The AM2023X is a versatile UV lamp that can be used in a variety of automotive manufacturing processes. It is a reliable and efficient tool that can help to improve the quality and performance of automotive products.

Other essential terms

- UV light: UV light is a type of electromagnetic radiation that has a wavelength shorter than visible light but longer than X-rays. UV light is used in a variety of applications, including curing coatings and adhesives, hardening plastics, and sterilizing components.

- Wavelength: The wavelength of UV light is the distance between the peaks of two consecutive waves. The wavelength of UV light determines its energy and penetration power.

- Seal type: The seal type of a UV lamp refers to the way in which the lamp is sealed. Roll-sealed lamps are more reliable and consistent in their performance than other types of UV lamps.

Understand AM2023X

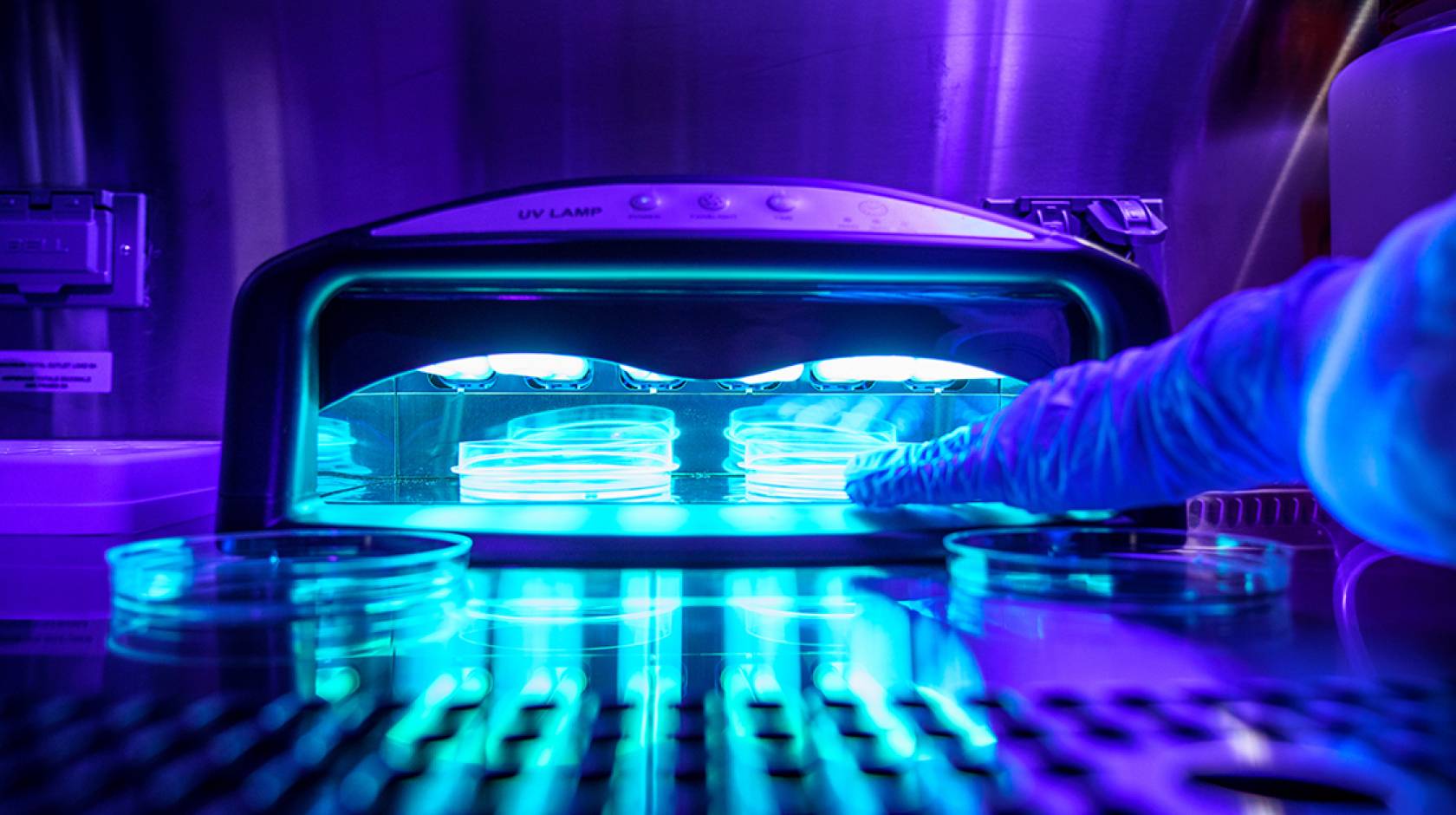

The AM2023X is a UV lamp that is used in automotive manufacturing. It is a high-power, roll-sealed lamp that is designed for applications that require a high degree of uniformity and consistency. The AM2023X is used in a variety of automotive manufacturing processes, including:

- Curing of coatings and adhesives

- Hardening of plastics

- Sterilization of components

- Detecting particles and contamination

The AM2023X is a reliable and efficient UV lamp that can help to improve the quality and performance of automotive products.

Applications of the AM2023X UV lamp:

The AM2023X is used in a variety of automotive manufacturing processes, including:

- Curing of coatings and adhesives: The AM2023X is used to cure coatings and adhesives that are used in a variety of automotive components, such as bumpers, spoilers, and headlights. The UV light from the AM2023X helps to ensure that the coatings and adhesives are cured properly, which improves their strength and durability.

- Hardening of plastics: The AM2023X is used to harden plastics that are used in a variety of automotive components, such as dashboards, door panels, and trim. The UV light from the AM2023X helps to improve the strength and stiffness of the plastics, which makes them more resistant to damage.

- Sterilization of components: The AM2023X can be used to sterilize automotive components that are exposed to the environment, such as air vents and door handles. The UV light from the AM2023X kills bacteria and viruses, which helps to prevent the spread of disease.

- Detecting particles and contamination: The AM2023X can be used to detect particles and contamination on automotive components prior to spraying. The UV light from the AM2023X makes particles and contamination glow, which makes them easier to see.

Features of the AM2023X UV lamp:

- High power output: The AM2023X has a high power output, which makes it suitable for curing coatings and adhesives, hardening plastics, and sterilizing components.

- Uniform beam: The AM2023X produces a uniform beam of UV light, which ensures that the curing, hardening, or sterilization process is consistent across the entire surface of the component.

- Long lifespan: The AM2023X has a long lifespan, which means that it can save money in the long run.

- Roll-sealed: The AM2023X is a roll-sealed lamp, which means that it is less likely to leak than other types of UV lamps. This makes it more reliable and consistent in its performance.

- Environmentally friendly: The AM2023X is designed to be environmentally friendly. It uses less energy than other types of UV lamps and does not produce harmful emissions.

These are just some of the features of the AM2023X UV lamp. There are many other features that make this lamp a valuable tool for automotive manufacturing.

Here are some additional features of the AM2023X UV lamp:

- It is easy to install and maintain.

- It is safe to use, with built-in safety features to prevent accidental exposure to UV light.

- It is available in a variety of power outputs and wavelengths, to meet the specific requirements of different applications.

The AM2023X UV lamp is a versatile and reliable tool that can be used in a variety of automotive manufacturing processes. It is a valuable investment for any automotive manufacturer that wants to improve the quality and performance of their products.

Benefits of the AM2023X UV lamp:

Here are some of the benefits of using the AM2023X UV lamp in automotive manufacturing:

- Improved quality and performance of automotive products: The AM2023X UV lamp can be used to cure coatings and adhesives, harden plastics, and sterilize components. This can improve the quality and performance of automotive products by making them stronger, more durable, and resistant to damage.

- Increased production efficiency: The AM2023X UV lamp can speed up the curing, hardening, and sterilization processes. This can lead to increased production efficiency and reduced costs.

- Improved safety: The AM2023X UV lamp can be used to sterilize components and prevent the spread of bacteria and viruses. This can improve the safety of automotive products and the people who work with them.

- Reduced environmental impact: The AM2023X UV lamp is designed to be environmentally friendly. It uses less energy than other types of UV lamps and does not produce harmful emissions.

These are just some of the benefits of using the AM2023X UV lamp in automotive manufacturing. There are many other benefits that can be realized by using this versatile and reliable tool.

Here are some additional benefits of using the AM2023X UV lamp:

- It can help to extend the lifespan of automotive components.

- It can make automotive products more resistant to fading and corrosion.

- It can improve the aesthetic appearance of automotive products.

- It can help to reduce the weight of automotive products, which can improve fuel efficiency.

The AM2023X UV lamp is a valuable tool for automotive manufacturers that want to improve the quality, performance, safety, and environmental impact of their products.

Comparison of the AM2023X UV lamp with other UV lamps

Here is a comparison of the AM2023X UV lamp with other UV lamps used in automotive manufacturing:

| Feature | AM2023X UV Lamp | Mercury Vapor Lamp | LED UV Lamp | Xenon Arc Lamp |

|---|---|---|---|---|

| Power output | High | High | Low | High |

| Wavelength | 254 nm | 254 nm | 365 nm | 185 nm |

| Penetration power | Deep | Deep | Shallow | Shallow |

| Uniformity | Good | Fair | Good | Fair |

| Lifespan | Long | Long | Short | Short |

| Cost | High | Low | Medium | Medium |

| Safety | Safe | Safe | Safe | Safe |

| Environmental impact | Low | High | Low | High |

The AM2023X UV lamp is a high-power, mercury vapor lamp that is designed for demanding applications. It has a deep penetration power and a long lifespan, making it ideal for curing coatings and adhesives, hardening plastics, and sterilizing components. However, it is also the most expensive type of UV lamp.

Mercury vapor lamps are the most common type of UV lamp used in automotive manufacturing. They are relatively inexpensive and have a long lifespan. However, they are not as powerful as other types of UV lamps and have a shallow penetration power.

LED UV lamps are a newer type of UV lamp that is becoming increasingly popular in automotive manufacturing. They are more efficient than mercury vapor lamps and have a longer lifespan. However, they are also more expensive.

Xenon arc lamps are the most powerful type of UV lamp, but they also have the shortest lifespan. They are typically used in applications where a high power output is required, such as curing thick coatings and adhesives.

The factors to consider when choosing a UV lamp for automotive manufacturing include:

- The power output required: The power output of the UV lamp must be sufficient to cure the coatings and adhesives or harden the plastics being used.

- The wavelength of the UV light: The wavelength of the UV light must be compatible with the materials being used.

- The penetration power of the UV light: The penetration power of the UV light must be sufficient to reach the depth of the material being cured or hardened.

- The uniformity of the UV light: The UV light must be evenly distributed across the surface of the material being cured or hardened.

- The lifespan of the UV lamp: The lifespan of the UV lamp must be sufficient to meet the needs of the application.

- The cost of the UV lamp: The cost of the UV lamp must be considered in relation to the other factors.

- The safety of the UV lamp: The UV lamp must be safe to use, with built-in safety features to prevent accidental exposure to UV light.

- The environmental impact of the UV lamp: The environmental impact of the UV lamp must be considered, especially if the lamp will be used in a closed environment.

The best type of UV lamp for automotive manufacturing will depend on the specific application. However, the AM2023X UV lamp is a versatile and reliable option that can be used in a variety of applications.

The Future of AM2023X UV lamps in Automotive Manufacturing

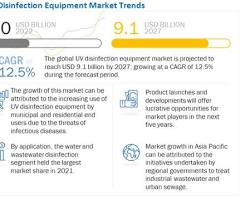

The future of AM2023X UV lamps in automotive manufacturing is bright. AM2023X UV lamps are versatile and reliable tools that can be used in a variety of automotive manufacturing processes. They are also relatively efficient and environmentally friendly.

Here are some of the trends in UV lamp technology that are expected to impact the automotive industry:

- The development of more efficient and environmentally friendly UV lamps: There is a growing demand for more efficient and environmentally friendly UV lamps. This is being driven by the need to reduce energy consumption and greenhouse gas emissions.

- The development of new applications for UV lamps: UV lamps are being used in new and innovative ways in the automotive industry. For example, they are being used to cure coatings and adhesives, harden plastics, and sterilize components.

- The development of automated UV curing systems: Automated UV curing systems are becoming increasingly popular in the automotive industry. These systems can help to improve production efficiency and reduce costs.

As these trends continue to develop, AM2023X UV lamps are expected to play an increasingly important role in automotive manufacturing. They will help to improve the quality and performance of automotive products, while also reducing energy consumption and greenhouse gas emissions.

Here are some specific examples of how UV lamps are improving the quality and performance of automotive products:

- UV lamps are used to cure coatings and adhesives, which can improve the strength, durability, and appearance of automotive products.

- UV lamps are used to harden plastics, which can make automotive products more resistant to damage.

- UV lamps are used to sterilize components, which can help to prevent the spread of bacteria and viruses.

- UV lamps are used to detect particles and contamination, which can help to improve the quality of the manufacturing process.

As UV lamp technology continues to develop, it is likely that even more innovative applications for UV lamps will be found in the automotive industry.

Also read: KACMUN: Korean American Coalition Model United Nations

Also read: GPT66X: Future version of a GPT model